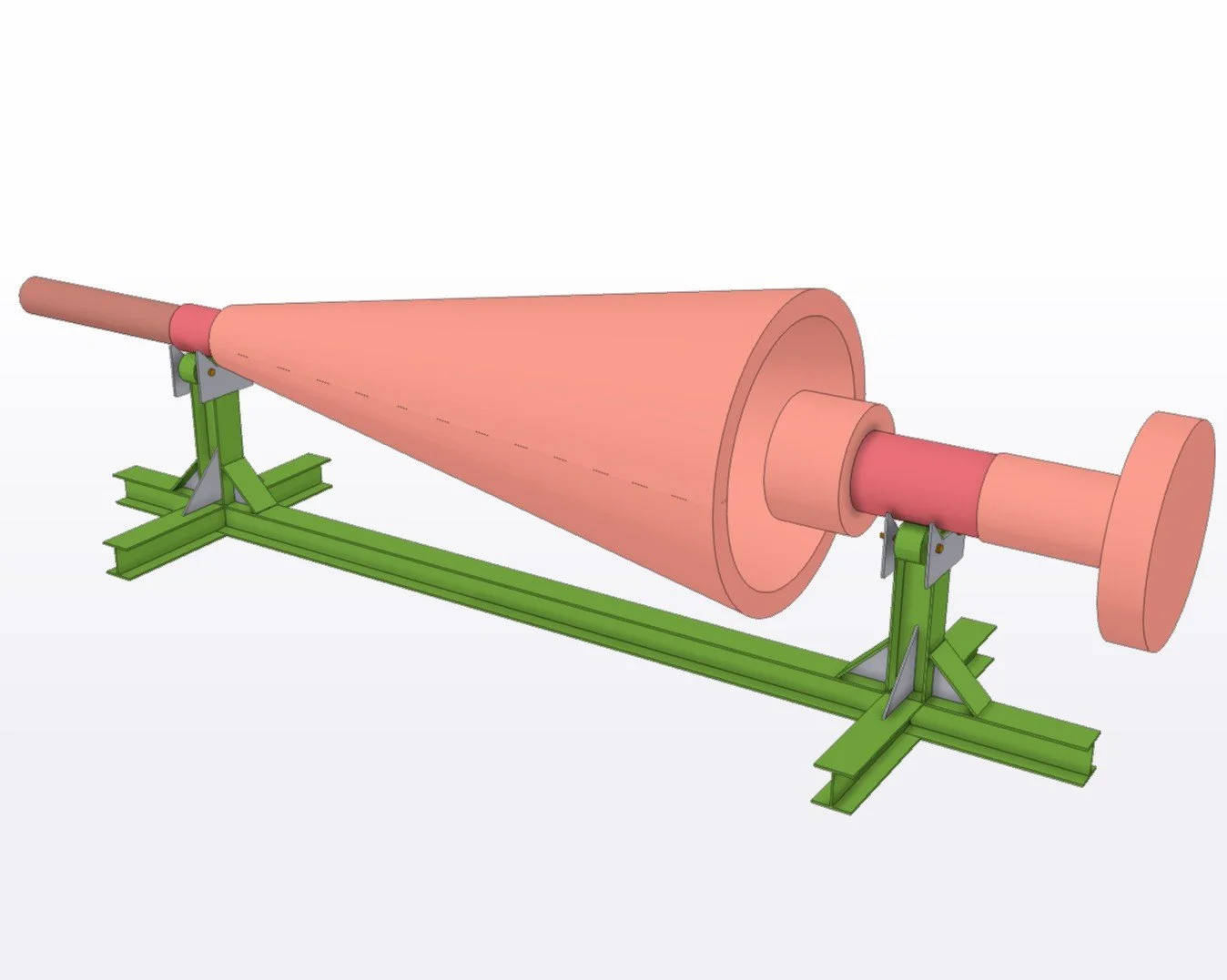

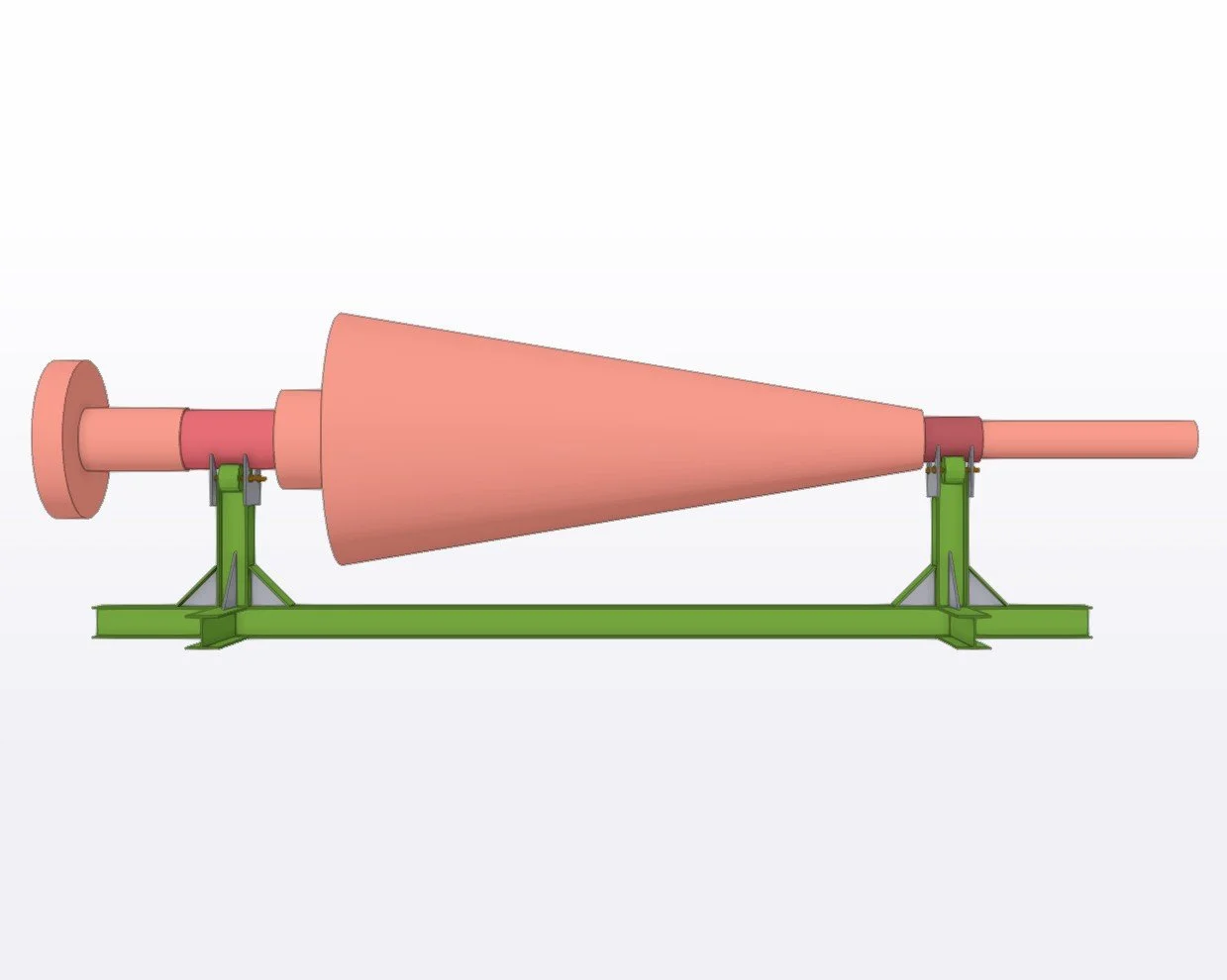

Turbine Rotor Transportation Frame

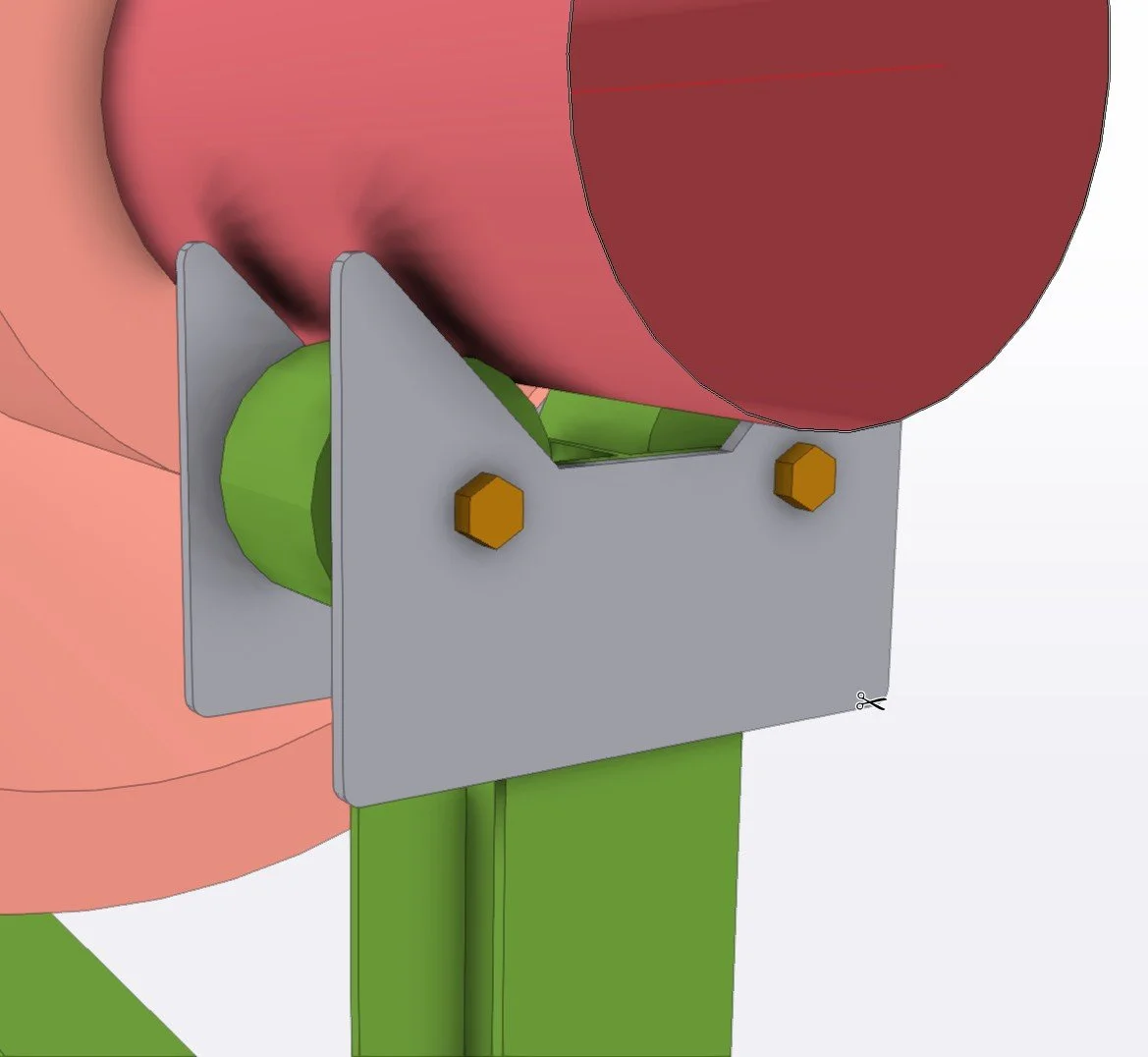

We were approached by a mechanical engineering and maintenance firm who had been instructed to remove, transport, inspect and repair the rotor from an industrial jet turbine. It is my understanding that this rotor was part of the electricity generation network for a large oil refinery. The frame was required to support the 6m long, 1.3m wide, 20 ton behemoth, not only in a workshop setting where it would be rotated on bearings and inspected, but it also had to withstand the forces of being transported at motorway speeds on the back of a lorry. We had to break out the old physics textbooks for this one! An, unfortunate, tid bit of information for this project is that - it was never used for transportation in the end; only inspection and repair in their workshop, which it still performed amazingly at, albeit overdesigned for only that use case. We never want to create unnecessary fabrication or recommend excessive material use; any part of a design should be justified structurally and with common sense in mind.